QIDI PET-GF 3D Printer Filament

PET-GF is specially developed for FDM 3D printing process. The substrate is made of PET engineering material, which has the characteristics of low moisture absorption, high strength, creep resistance, solvent resistance and high heat resistance. It has good dimensional stability during printing, no warping, no shrinkage, no odor, and no need for environmental insulation.

Say goodbye to warping

The molecular chain structure of PET is highly regular and has a rigid ring structure, which makes PET have good mechanical properties, small deformation under long-term load, and better creep resistance than PA and PC materials.

PET-GF prints are suitable for special environments

PET-GF further enhances the rigidity, hardness and wear resistance of the material by adding chopped glass fibers. At the same time, glass fibers can inhibit the warping behavior of PET during printing, so that PET-GF only needs 70-80℃ base plate heating when printing, and does not require cavity insulation, making it very easy to print. Its 3D printed parts are suitable for use environments that require high heat resistance and long-term stress, such as 3D printer hot end parts.

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate | QIDI PEI Plate, HF Plate and Smooth Plate | PC Plate |

| Hotend | Hardened Steel Nozzle ( 0.4 / 0.6 / 0.8 mm),Bimetal Nozzle ( 0.4 / 0.6 / 0.8 mm),Tungsten Carbide Nozzles( 0.4 / 0.6 / 0.8 mm) | Brass/Copper plated Nozzle (0.2/0.4/0.6/0.8 mm) |

| Glue | Glue Stick/ 3D LAC adhesive spray | / |

| Recommended Printing Settings | |

| Drying Settings (Blast Drying Oven) | 100-120 °C, 4-8 h |

| Printing and Keeping Container’s Humidity | < 15% RH (Sealed, with Desiccant) |

| Nozzle Temperature | 260 - 320 °C |

| Bed Temperature (with Glue) | 80 °C |

| Printing Speed | 30-200 mm/s |

| Physical Properties | |

| Density | 1.38 g/cm³ |

| Vicat Softening Temperature | 148.8 °C |

| Heat Deflection Temperature | 86.7 °C |

| Melting Temperature | 251 °C |

| Melt Index | 5.3 g/10 min |

| Mechanical Properties | |

| Unannealed/Annealed | |

| Tensile Strength | 64.65±3.12 MPa/70.86±2.86 MPa |

| Breaking Elongation Rate | 1.14±0.11 % |

| Bending Modulus | 3201.0±57.42 MPa/3650.32±65.81 MPa |

| Bending Strength | 98.62±0.84 MPa/114.87±3.0 MPa |

| Impact Strength | 12.68±1.61 kJ/m²/6.56±0.68 kJ/m³ |

Printing Tips

Additional Suggestions

1. Although the moisture absorption of PET material is very low, it is very sensitive to moisture. Printing after absorbing moisture will result in oozing, extruding with bubbles and rough surface appearance, thus reducing print quality. It is recommended that put the filament into a dry box (humidity below 15%) immediately after opening the QIDI PET-GF vacuum foil bag for printing. Please put the unused filament back into the original aluminum foil bag for sealed storage.

2. After the material is damp, there will be more printing oozing, bubbles extruded and rough printing surface. Please dry the filament in an oven at 100-120℃ for 4-6h to restore the printing quality of QIDI PET-GF.

3. Hardened steel and above grade nozzles shall be selected, which can effectively improve the print quality. Besides, it is recommended that the thickness of the heating block should no less than 12mm.

4. After the printing, the printed part can be annealed to further improve the strength of QIDI PET-GF print part. Annealing conditions: place the printed part at 80-100℃ for 4-8 hours and cool to room temperature naturally.

5.The filament has a high content of short-cut glass fiber and has been factory-dried, which makes it more brittle and prone to breaking. This is a normal phenomenon.

Arrival time

Expected to be in stock in local warehouses in 1-2 months.

If you want to get it before then, you can choose to buy it from China, but you should also handle the customs clearance for shipments from China on your own.

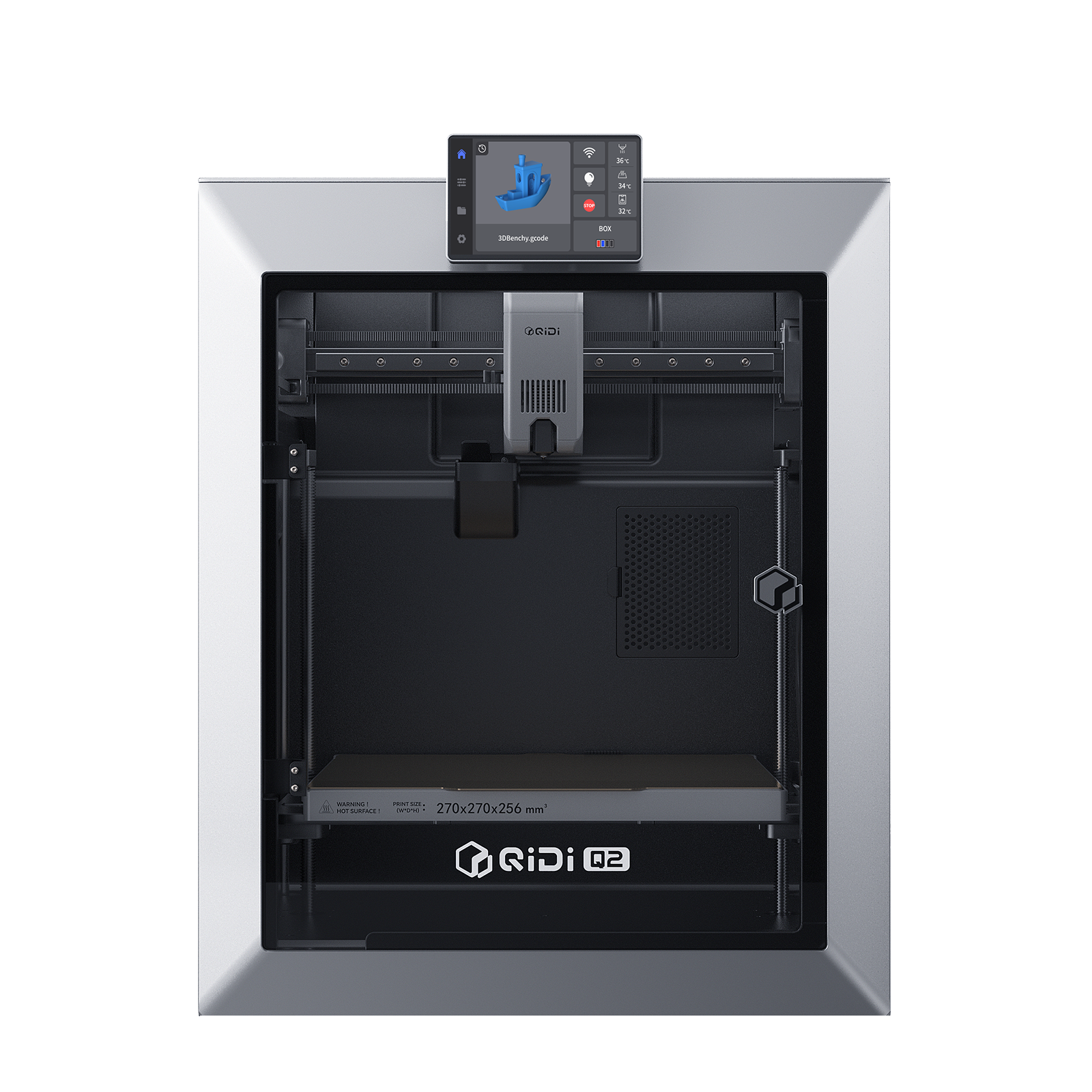

Q2

Q2

Plus 4

Plus 4

QIDI Box

QIDI Box

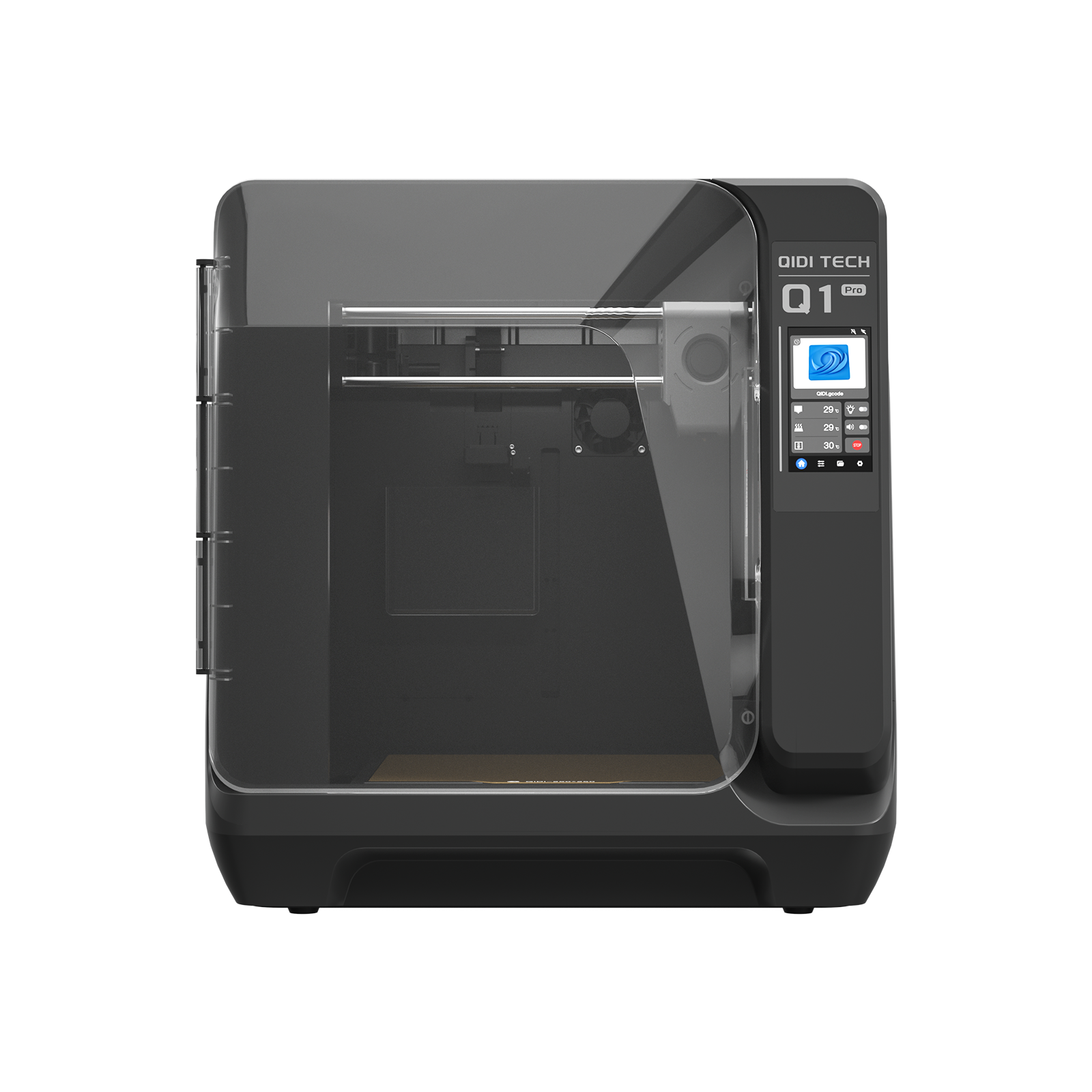

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3