Third Gen Active Chamber Heating

What Can QIDI Max4 Do?

@亖葱

@Borderlands

@pulsardesigns

Industry-First Innovations of QIDI Max4

How Do We Break the Limits

All Filaments Enter the Era of Chamber Heating

Clog-Free, Even in a Heated Chamber

Active Cooling Air Control System

in combination with active chamber heating, ensure that large-sized PLA does not warp at the edges

Reduce the Clogging Situation by 90%

Efficiency air-cooled direct-blow extruders and filament

Third Gen Active Chamber Heating Reaches up to 65ºC

The air circulation design ensures ideal conditions for printing various filaments

Chamber Heating & Polar Cooler ON

ensure that large-sized PLA does not warp at the edges

Printing Enters the Era of Industrial-Grade Precision

No Wobble, No Ripple

With The Shortest Z Travel in Its Class, 2 mm lead Z-axis screw — delivering unprecedented precision. With the new anti-backlash nut, every layer stays perfectly aligned

Ultra-Smooth Layer Detail

Every Inch Heated — For the First Time

Heated Bed Enters the Industrial-Grade Temperature Control Era

The 390×390 mm heated bed features a full-surface silicone layer with dense heating wires and insulation cotton, ensuring even heat, strong first-layer adhesion, and stable temperatures—perfect for large, warp-free prints

Efficient industrial-grade output, Unlock size

Powerful FOC Closed-Loop Stepper Motor

The motor performance has been enhanced by 65%, and the printing speed has been increased to 800mm/s, The acceleration is increased to 30,000 mm/s²

Build volume 390×390×340 mm

Let your imagination break free from volume constraints

Heating up to 370ºC

With ceramic throat and new heat dissipation module to reduce clogging.

Bimetal hardened steel nozzle for increased durability

Engineered for high-performance demands

New 1.5GT Custom Belt

New 1.5GT custom belt with higher tooth density for smoother, more precise motion.

Minimizes vibration frequency artifact (VFA) for better print quality

An Epic Upgrade in

Stability and Precision

Upgrade to Linear Guide Rail

Maintains smooth performance and accuracy over long-term use

CoreXY Full Metal Frame

The overall motion structure uses a full metal frame and bearings, delivering QIDI's signature stable and reliable manufacturing quality

Flagship-Level Smooth Surface

QIDI Max4

Others

The nozzle acts as the sensor, ensuring truly zero deviation

No probe offset, no guesswork, just precise real contact

Unaffected by bed surface or environmental vibrations, it delivers unmatched first-layer accuracy, zero offset, and true plug-and-play leveling

5-inch Touch Screen

The high-definition touch screen and the upgraded powerful processor, combined with the new generation of UI design, bring an intelligent and understandable user operation experience

AI camera, Ensuring Every Print

Actively detect common printing problems such as Spaghetti, to ensure the safety of your printer

Multi-color and multi-material printing

The QIDI Box features a built-in chamber heating up to 65°C, gently softening advanced filaments for smooth, vibrant multi-color prints every time

Highlights of QIDI BOX

Your Personal Color Partner

For Home Health and Safety

Highly efficient at capturing 99.5% of dust and particles

Multi-Sensor Closed-Loop Temperature Control

Flame-Retardant Chamber

uses a lot of flame-retardant materials in the chamber design to provide fire safety protection

User Experience Upgrade

QIDI Max4 has undergone design upgrades based on user feedback, offering a more comfortable experience

QIDI Max 4, ready for action

Why Choose QIDI Max4

What's in the box

QIDI Max4 Technical Specifications

|

Print Size (W*D*H) 390*390*340 mm |

Printer Dimensions 558*578*612 mm |

|

Package Dimensions 700*710*750mm |

Gross Weight Max4:49.5kg Max4 Combo:56kg |

|

Net Weight Max4:40kg Max4 Combo:46.5kg |

Print Head Temperature ≤ 370℃ |

|

Included Build Plate TypeDual-Sided Textured PEI Plate |

Hot Bed Temperature ≤ 120℃ |

|

Max Speed of Tool Head 800mm/s |

Acceleration ≤30000mm/s² |

|

XY Structure CoreXY, 1.5GT 10mm Width Belt FOC Closed-loop Stepper Motor |

X/Y Axis X: High Hardness Linear Guide Rail Y: 12mm Linear Steel Shafts |

|

Z Axis Independent 2mm lead screw motors ×2 12mm Linear Steel Shafts ×4 |

Printing Platform Aluminum Plate Silicone Heated Bed |

| Nozzle Bimetal Nozzle | Nozzle Diameter 0.4mm (0.2/0.6/0.8mm Optional) |

|

Extruder Gear Direct Extruder Hardened Steel Dual Gears |

Supported Filament PLA, ABS, ASA, PETG, TPU, PA, PC, Carbon/ Glass Fiber Reinforced Polymer,etc. |

| Filament Diameter 1.75mm | Multi-Color Printing Compatible with QIDI Box(Multi-color) |

|

Air filter Yes(3-in-1 Air Filter: G3 Pre-Filter + H12 HEPA + Coconut Shell Activated Carbon) |

Chamber Temperature(PTC Heater) 3rd Gen Up to 65° C Independent Chamber Heating |

|

Automatic Leveling Hands-free Automatic Leveling (Loadcell Sensor Integrated into the Hotend) |

Filament Detection Run Out Sensor(mounted above extruder) Tangle Detection(QIDI BOX required) |

| AI Camera Detection Yes | Auxiliary Part Cooling Fan 4-Pin PWM Fan with RPM Feedback |

| Hot End Cooling Fan 4-Pin PWM Fan with RPM Feedback | Model Cooling Fan 4-Pin PWM Fan with RPM Feedback |

| Extruder Cooler Yes (Polar Cooler required) | Status RGB LED Yes |

| Power Loss Recovery: Yes | Input Shaping Yes |

| Voltage 110V / 220–240V AC, 50/60Hz (region-specific models available) | Rated Power 150W+500W(Chamber Heating)+700W(Heating Bed) |

| Camera Camera (Up to 1080P) Timelapse Supported | Storage 32G EMMC and USB2.0 Flash Drive |

| Connectivity 2.4GHz/5GHz Wi-Fi, Ethernet, USB | Display Screen 5 Inch 800*480 Touch Screen |

| Slicer QIDI Studio and other third-party software, such as Orca,PrusaSlicer etc. | File Formats for Slicing STL, OBJ, 3MF,STEP,STP,etc. |

QIDI Max4 TDS

DownloadFrequently Asked Questions For QIDI MAX4

We recommend leaving additional clearance at the back, sides, and top of the printer. This extra space makes it easier to change filament and ensures proper ventilation and cooling during operation.

• QIDI Cloud: Connect to the QIDI cloud server for remote monitoring and control.

• Wi-Fi: Supports 2.4GHz/5GHz networks.

• Ethernet (LAN): Connect via a wired network port for stable remote control within your local network.

• Offline Printing: Use a USB drive to load your files and print completely offline.

Due to the flexible nature of TPU filaments, there are some operational issues that can arise during feeding and printing. To facilitate TPU printing, we have created a dedicated Wiki guide. Simply follow the instructions in the Wiki to successfully print with TPU filaments:TPU printing guide

The printer supports multiple file formats, including STL, OBJ, 3MF, and STEP/STP.

Unlike standard desktop printers, the Max4 delivers industrial-grade stability, uniform heat distribution(chamber and build bed), and consistent results on large-format prints. Whether for rapid prototyping, functional parts, or small-batch production, the Max4 provides faster workflow, higher success rates, and unmatched material versatility—making it a true high-performance flagship in its class.

(1)A higher chamber temperature can reduce part cooling efficiency, which may negatively affect overhang and bridging performance.

(2)The chamber temperature should be set to approximately 10°C below the filament’s softening temperature to prevent the filament from softening prematurely. Excessive chamber heat may impact extrusion and retraction performance and could increase the risk of nozzle clogging.

For example, when printing PLA, it is recommended not to set the chamber temperature above 45°C.

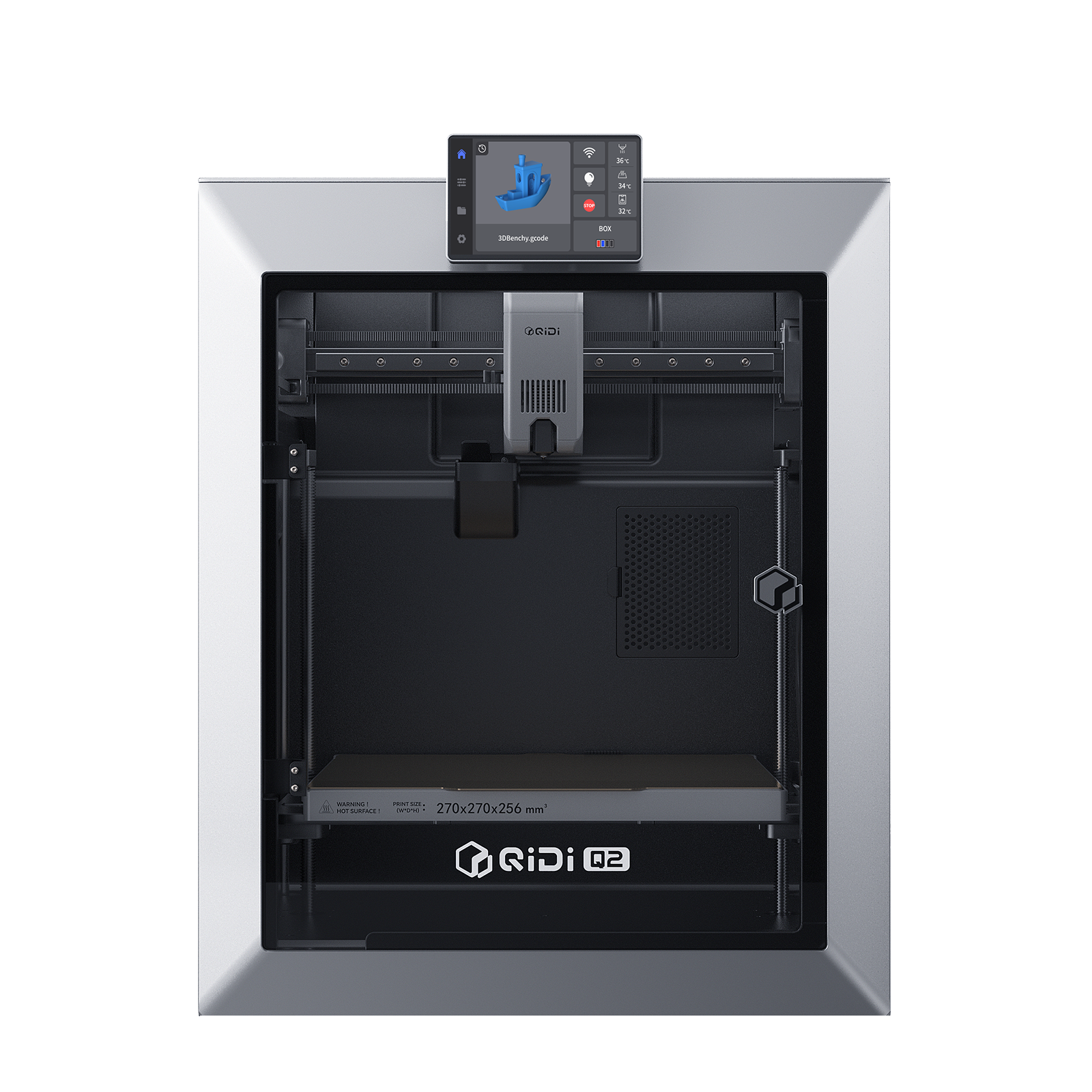

Q2

Q2

Plus 4

Plus 4

QIDI Box

QIDI Box

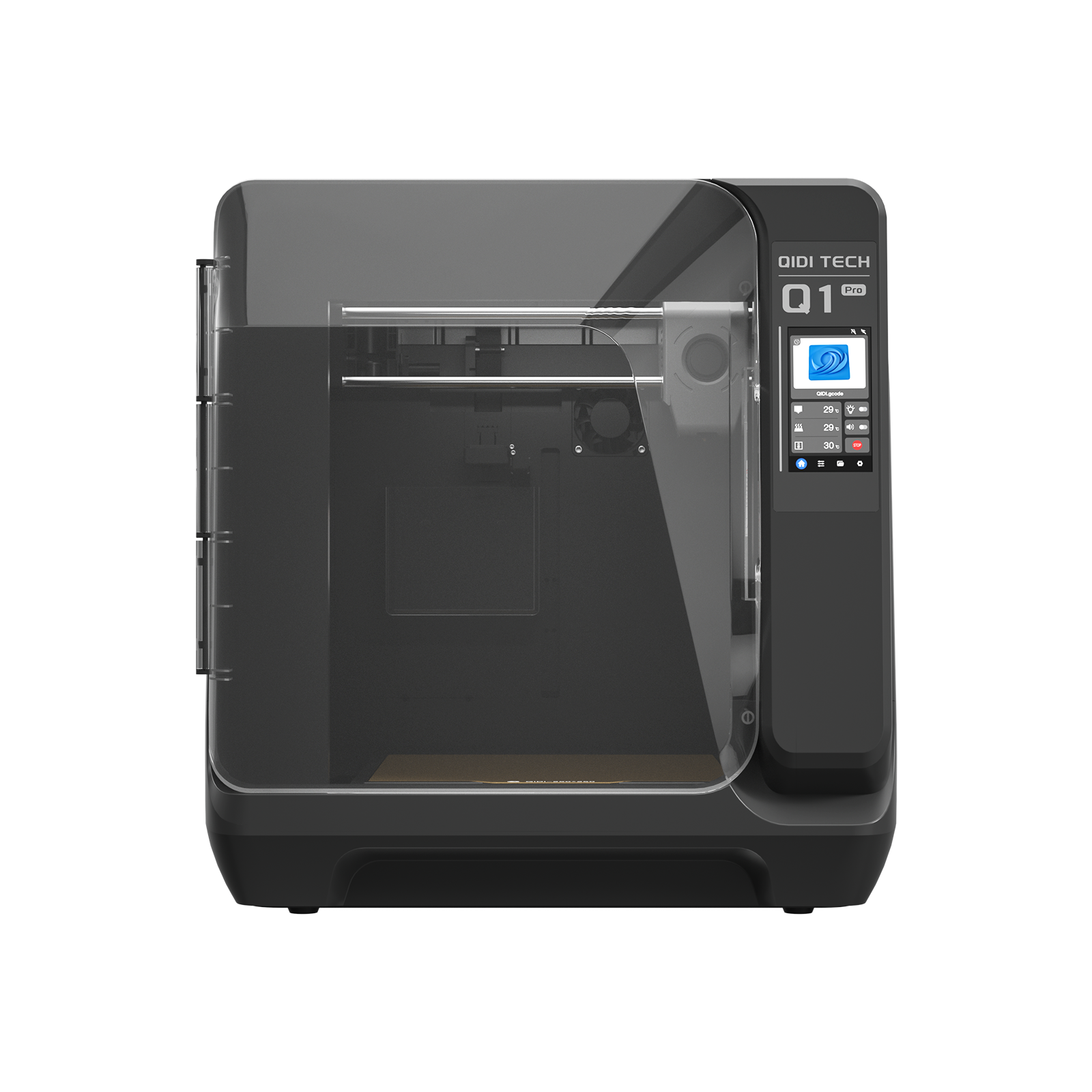

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3