How to Print PPS-CF Filament Perfectly?

QIDI PPS-CF is a carbon fiber reinforced polyphenylene sulfide (PPS) composite material designed for near-industrial-grade 3D printing results. This advanced filament combines PPS with carbon fiber, endowing PPS-CF with exceptional properties, including outstanding solvent resistance, corrosion resistance, heat resistance, flame retardancy, ultra-low moisture absorption, and superior mechanical performance. This comprehensive guide will cover pre-print drying operations, recommended print settings, and annealing treatments to help you achieve flawless, professional-quality prints with ease.

1. How to Perfectly Dry QIDI PPS-CF Carbon Fiber Filament?

Due to its inherent hygroscopic nature, QIDI PPS-CF filament is prone to absorbing moisture after opening. Therefore, proper drying before printing is crucial to ensure optimal print quality, prevent common issues, and achieve the best mechanical properties.

Drying Operation:

- Ensure the surface of the PPS-CF filament is sufficiently clean and free of any foreign objects or dust.

- Place the PPS-CF filament spool into a dedicated filament dryer box or a blower dryer.

- Set the dryer temperature to 120°C (248°F). The recommended drying time is 8 hours, though this can be adjusted based on the filament's humidity level and exposure to moisture. Ensure the filament is thoroughly dry.

- Initiate the drying process.

Additionally, for long-term storage, it's vital to keep PPS-CF filaments in a sealed containerwith a desiccant, ensuring the relative humidity inside the container remains below 20% RH to preserve its print performance and the strength of your final parts.

2. Recommended Printing Parameters and Accessories for QIDI PPS-CF (Achieving Optimal Results)

To ensure successful prints and achieve high-quality, dimensionally accurate parts with QIDI PPS-CF filament, we recommend using the following accessories and print settings (using the QIDI Plus 4, which features a high-temperature chamber and precision printing capabilities, as an example):

Recommended Accessories:

- Build Plate: QIDI PEI Plate or Smooth Plate (These offer excellent adhesion, crucial for preventing warping with high-performance materials).

- Hotend: Hardened Steel Nozzle (0.4 / 0.6 / 0.8 mm) or Bimetal Nozzle (0.4 / 0.6 / 0.8 mm) - The carbon fiber content in PPS-CF is abrasive. Using these wear-resistant nozzles will extend their lifespan and ensure consistent print quality.

- Drying Box: During printing, it is essential to keep the filament in a filament drying box. This continuous drying prevents moisture absorption during the print job, which can lead to issues like stringing, weak layer adhesion, and rough surface finish.

Recommended Printing Parameters:

- Nozzle Temperature: 320-350°C (This high temperature ensures the material melts thoroughly, promoting excellent flow and strong layer bonding).

- Bed Temperature: 100-110°C (Helps minimize warping and improves first-layer adhesion, especially critical for larger prints).

- Printing Speed: 30-100mm/s (Adjust within this range based on model complexity and printer capabilities; start with lower speeds for initial tests and gradually increase).

- Printing Fan: 0~30% (Lower fan speeds help maintain the print's temperature, reducing thermal stress and improving part strength, particularly for high-temperature materials).

3. How to Perform Annealing Treatment on QIDI PPS-CF Printed Parts?

Annealing is a post-processing technique involving heating and then controlled cooling of materials to alter their physical properties. In 3D printing, annealing is a key step to significantly improve the performance of printed parts by eliminating residual thermal stress, thereby enhancing strength, heat resistance, and dimensional stability. However, the effectiveness of annealing is influenced by factors such as material type, annealing temperature, and duration. Improper operation, especially for complex models, can lead to undesirable results like deformation or warping.

For optimal annealing results, it is highly recommended to use a blast drying oven or an industrial oven capable of precise temperature control.

Detailed Annealing Treatment Steps for QIDI PPS-CF Printed Parts:

- Place the printed items on a tray, ensuring they are evenly spaced to allow for uniform heating and prevent hot spots.

- Preheat the oven to 120°C (248°F). Ensure the oven reaches the target temperature before placing the parts inside.

- Place the printed parts into the preheated oven. Let them stand and dry for at least 6 hours. For larger or more complex models, a longer annealing duration might be beneficial.

- Turn off the drying oven and allow the items to cool down slowly to room temperature inside the oven. Avoiding rapid temperature changes is crucial to prevent deformation or cracking and ensure the final dimensional accuracy of the model.

- Once completely cooled, carefully remove the tray and take out the annealed printed parts.

4. What Are the Key Advantages of QIDI PPS-CF? (Why Choose It?)

a. Ultra-High Resistance to Heat and Flames: Reliable Guarantee for Key Areas

QIDI PPS-CF boasts a remarkable heat deflection temperature of up to 264°C (507°F) and achieves a UL-94 V-0 flame retardant rating. This makes it an ideal choice for applications requiring exceptional thermal stability and stringent fire safety standards, providing reliable assurance for critical components.

>b. Excellent Solvent and Chemical Resistance: Ideal for the Chemical Industry

At temperatures below 200°C, QIDI PPS-CF is almost insoluble in any solvent and demonstrates strong resistance to acids, bases, and salts under normal conditions. This outstanding chemical inertness makes it perfect for use in the chemical industry, fluid handling systems, and environments exposed to corrosive substances.

c. Ultra-Low Water Absorption: Best Choice for Demanding Moisture-Proof Requirements

With an extremely low moisture absorption rate of just 0.05%, QIDI PPS-CF is highly suitable for applications in humid or underwater environments. This includes parts like pump impellers, marine components, and diving equipment parts, where dimensional stability and mechanical performance must not be compromised by moisture.

>d. Excellent Mechanical Properties: Meeting High Precision and Demanding Application Needs

PPS-CF combines the inherent stiffness of polyphenylene sulfide (PPS) with the superior reinforcing capabilities of carbon fiber. This synergy results in outstanding stiffness, bending strength, and tensile strength, enabling the material to meet the requirements of various high-strength and high-precision applications.

QIDI PPS-CF, with its excellent resistance to solvent, corrosion, heat, and flames, ultra-low water absorption, and superior mechanical properties, demonstrates extraordinary application prospects across sectors like aerospace, automotive manufacturing, electronic equipment, and chemicals. By choosing QIDI's professional 3D printing filaments and pairing them with the latest QIDI Plus4 high-speed 3D printer, you'll be at the forefront of technological innovation, easily achieving quasi-industrial-grade printing effects. We look forward to exploring even more printing possibilities with you in the future!

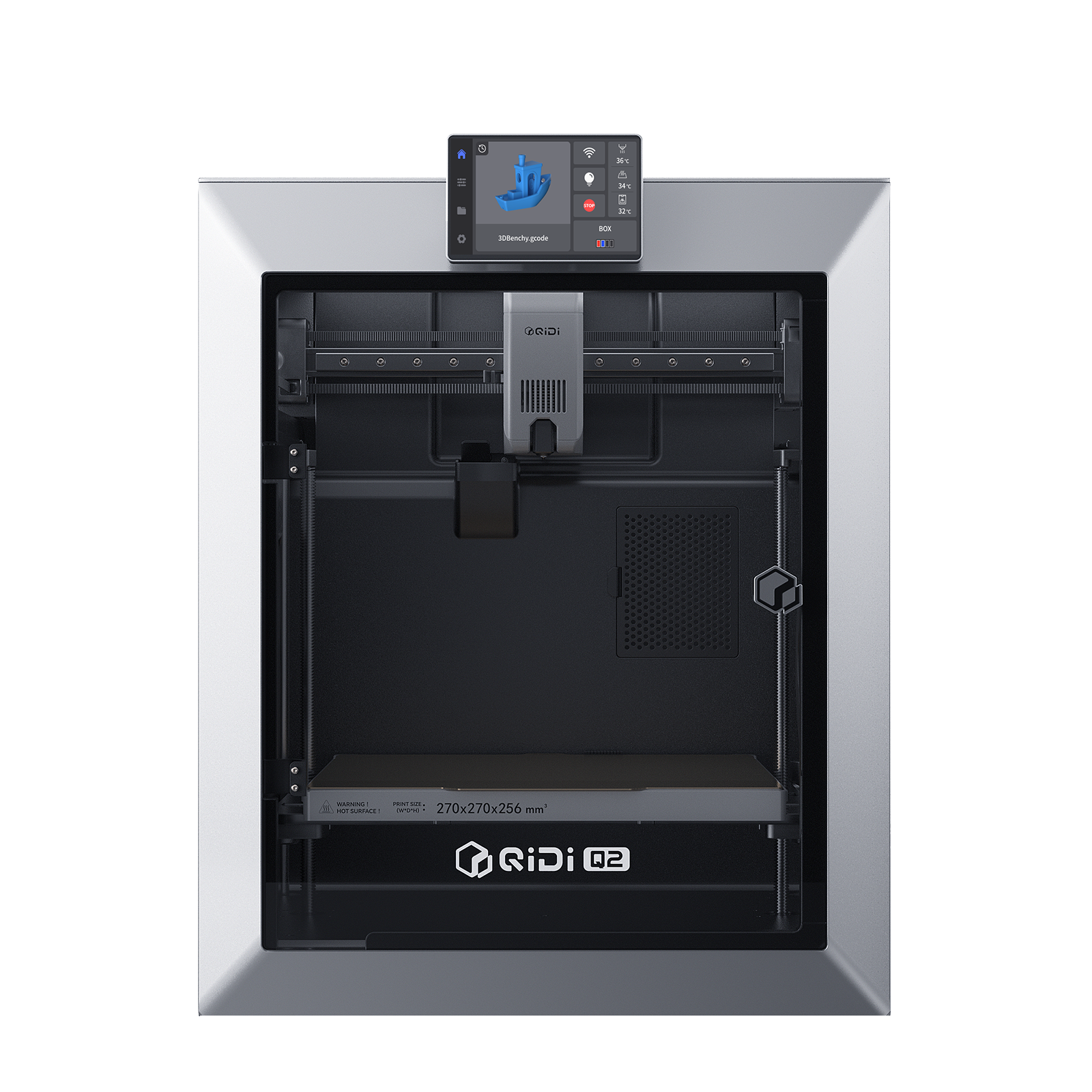

Q2

Q2

Plus 4

Plus 4

QIDI Box

QIDI Box

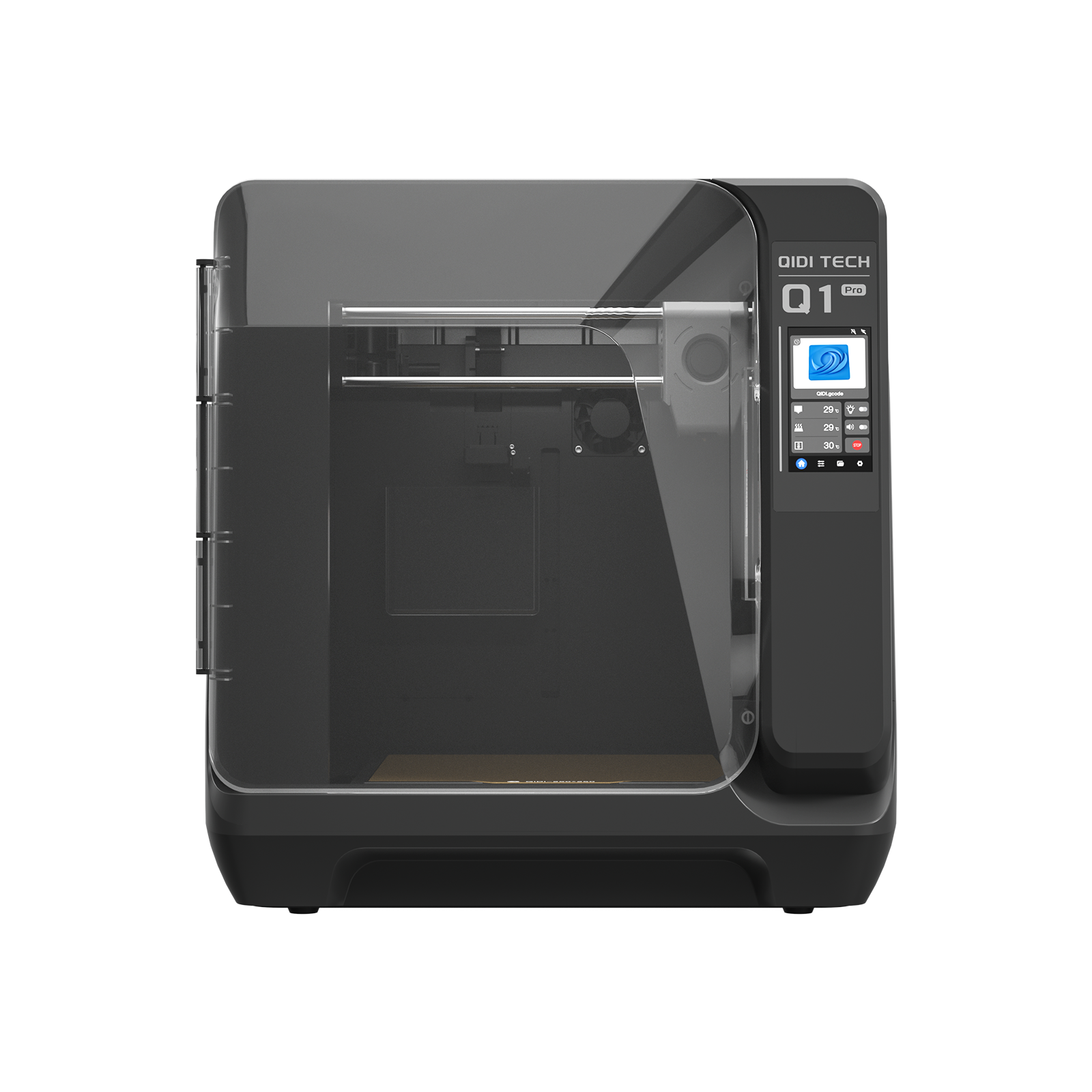

Q1 Pro

Q1 Pro

X-Max 3

X-Max 3